As a designer it was my responsibility to create designs that correspond to fit, form, and function of desired engineering requirements.

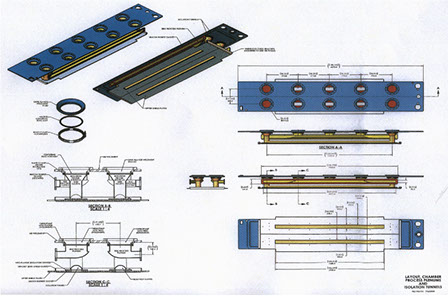

Layout of a new vacuum chamber assembly for an industrial glass coating system.

Technology is similar to thin film coating on semiconductor wafer chips except on a larger scale for architectural safety glass for buildings like skyscrapers.

Applied Materials, Fairfield CA 2009.

THE CONCEPTUAL LAYOUT

The Conceptual Layout communicates details of the design without a formal format. The drawing is an engineering brainstorming sketch. The starting point that prepares engineering for the research tasks ahead. Once everyone is in agreement, the project continues into finer detail until there is enough research and development to start extracting piece parts of the layout to fabricate a prototype.

It’s during this planning phase were key decisions are made in directing the development plan.

Normal design procedures consisted of material research, selection of vendor parts, frequent interface with fabricators, , design reviews, and drawing management planning.

The designer should keep in mind cost estimates, risk assessments, time management, and safety requirements during the design phase. Should also incorporate mass property requirements to help engineering determine static weights, tensile strengths, stress points, and the center of gravity of the design.